SmartBolts® DTI™

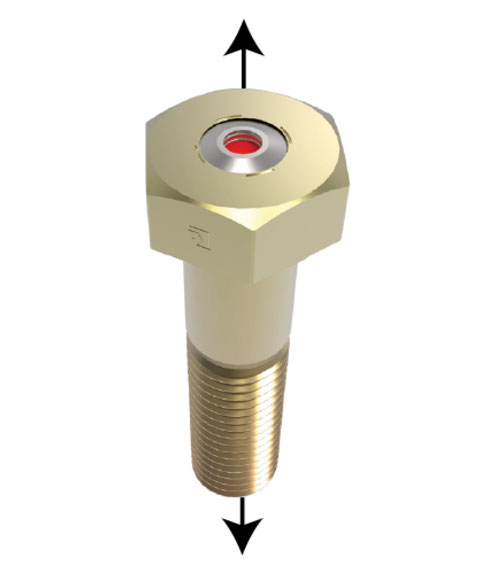

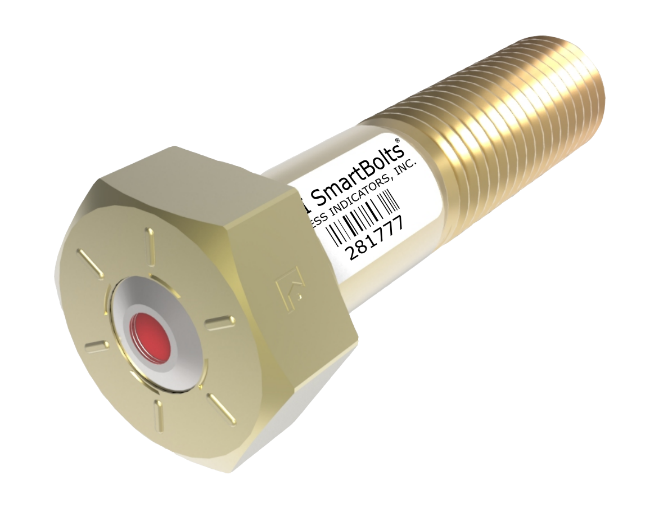

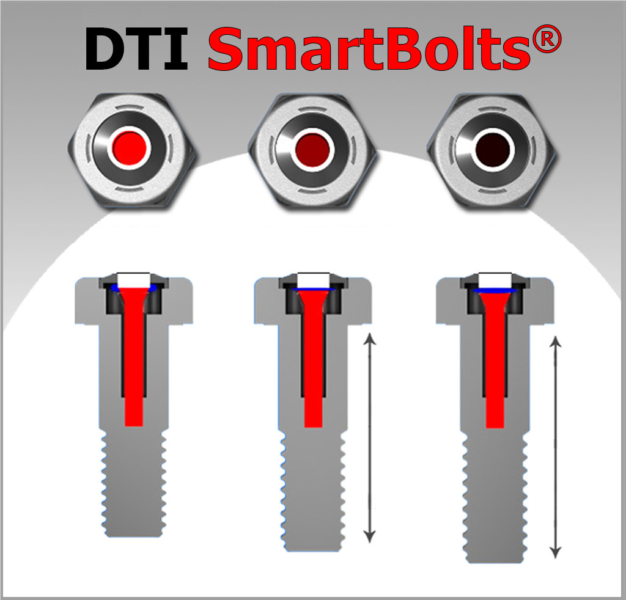

The DTI Visual Indication System™ continuously measures and displays tension information. From loose to tight and back again, the system is reliable and repeatable through countless cycles of operation. It is compatible with a wide range of fastener types, and we can adapt it to fasteners of nearly every available grade, finish, and coating.

Engineering team can design the DTI Visual Indication System to meet the specific requirements of your application. During the design phase, a Design Tension is specified. The Design Tension identifies a properly tightened SmartBolt.

DTI (Direct Tension Indicating) SmartBolts directly correlate fastener tension with colour. Accuracy and reliably is ensured because the colour change of the DTI Visual Indication System™ is proportional to fastener stretch — the only true measure of how tight your joint is (torque readings can be misleading since torque only measures how difficult it is to turn the bolt head).

| Hexagon head bolt | Hexagon flange bolt | Inbus screw | Stud bolt, threaded rod | |

|---|---|---|---|---|

| Diameter (min.) | M10 | M12 | M24 | M20 |

| Diameter (max.) | M64 | M64 | M64 | M64 |

| Length | 30 mm – 400 mm (on request other) |

| Grade | 8.8 (Gr. 5), 10.9 (Gr. 8), stainless steel, others |

| Surface protection | Plain (black), zinc plated, hot dip galvanised, aluminium zinc flake, other finishes on request |

| Thread | Partial or full thread |

| Design tension range | 30-90% of modified proof strength |

| Accuracy | +/- 10% of design tension |

| Operational temperature range | -20 °C up to +75 °C |