RotaChock® Mounting plate

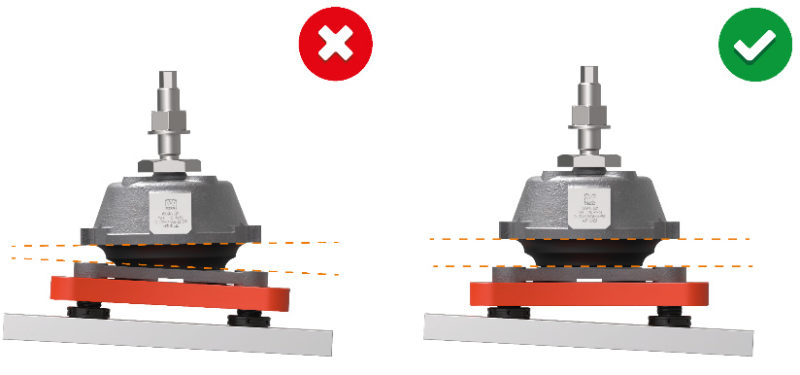

The installation of resilient mounts can be challenging because the base of the rubber mount needs to be aligned perfectly parallel to the machine foot to ensure optimal damping characteristics and life cycle of the rubber. The traditional way to set up the resilient mount is to use the 4 adjustment bolts to eliminate any angle between the cap and the base plate, and then to fill the gap between the base plate of the mount and the foundation structure with either 2-compound epoxy resin or a custom made fitted steel plate.

The RotaChock® Mounting Plate offers an adjustable alternative to epoxy resin or tailor-made steel chocks. The adjustment bolts can be used to eliminate any angle between the foundation and base plate of the mount, after which the 4 chocks at the corners are adjusted to the correct height. The base plate, mounting plate and foundation are then securely tightened together with the 4 foundation bolts.

The system is very flexible and can be re-adjusted at any time if necessary. The time required to finish a typical installation can be cut back from several days to only a few hours.