Oxygen service

Developed and tested for safety.

Oxygen – essential for life yet so dangerous, posing huge potential risk when utilised in industrial processes. To ensure the safety of plant and personnel, extreme caution is required to ensure that all systems used for handling oxygen are correctly specified, designed, manufactured and maintained because the smallest error at any stage can prove catastrophic.

Although oxygen itself does not burn, it supports combustion. The more oxygen present in a system the greater the risk of fire occurring and the lower the temperature at which ignition will occur until, in its purest form, it can cause the rapid or spontaneous combustion of most materials – even metals.

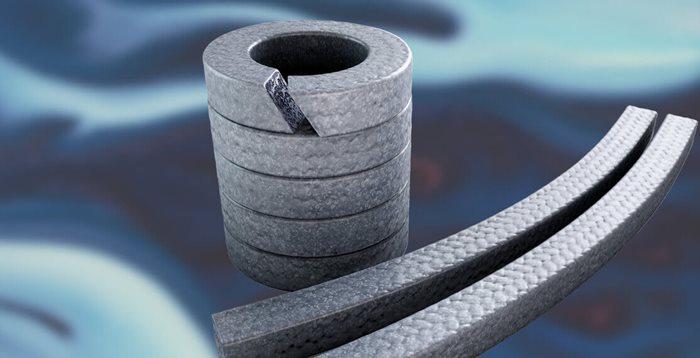

Supagraf® OX

A graphite yarn compression packing designed for valves in oxygen service.

Supagraf® OX has been developed specifically for valve services with gaseous and liquid oxygen, to provide safe operation and low emission rates. This valve stem packing is manufactured in a clean room environment, from yarn to finished product. It comprises high purity flexible graphite yarn treated with oxidation inhibitors. The yarns are individually reinforced with Inconel® 600 wire mesh.

Product features

- Manufactured in a clean room environment, from yarn to finished product

- High purity flexible graphite yarn treated with oxidation inhibitors

- Yarns individually reinforced with Inconel® 600 wire mesh

Typical applications

- Supagraf® OX is designed for valves handling gaseous or liquid oxygen

- For applications involving media other than oxygen, please contact us for further advice

- Supagraf® OX is NOT suitable for use with control valves where fine adjustment is required, as this is a dry product that does not contain a lubricant package

Performance

For gaseous oxygen service up to +60 °C (+ 140°F):

- Maximum oxygen pressure 44 MPa / 440 bar (6382 psi)

For gaseous oxygen service from + 60 °C (+ 140 °F) up to + 300 °C (+ 572 °F):

- Maximum oxygen pressure 25 MPa / 250 bar (3626 psi)

For liquid oxygen service:

- Limit service pressure to 45 MPa / 450 bar (6527 psi)

How supplied

- All popular square sections from 3 mm to 25 mm (1/8” to 1″) in boxes containing 8 m (26′ 3″), or in coil form by the metre / foot or kilogram / pound

- Also supplied as split preformed rings and sets

Approvals & certifications

- BAM certified

- Shell MESC SPE 85/204

- Shell MESC SPE 77/303