Packing for valves

The right packing for every valve application.

Industries across the world rely on our packings to help keep their valves operating efficiently day-in and day-out – with energy saving benefits and the minimum of fugitive emissions. James Walker®’s constant advances in materials and lubricants, product design and manufacturing techniques bring you compression packings to match both your modern fluid handling systems and your older plant. Whatever your requirement, our expertise and over 135 years of experience in compression packing materials can be brought to bear on providing a customised solution:

- World-beating fugitive emission control

- Premium and value options yet always high performance

- State-of-the-art materials to traditional ‘natural’ yarns, many developed in-house

- Materials suited to the most abrasive and chemically aggressive environments

- Products tolerant of poor mechanical conditions

- Meeting specialist requirements for potable water, food or oxygen duties

- Designed for sealing challenging molten salt media used in renewable energy sectors such as solar power generation, and for use in hydrogen service

- Multi-capability products that allow reduction of stockholding levels, as one packing can serve many different valves on the same site

- Fitting guides for all packing applications

Highpurity white packing, cross plaited from tough, thermally stable PTFE fibre yarn for use in valve and potable water applications.

Formerly known as Fluolion® Filament D, Lionpak® 2100 is a high-purity white packing, cross-plaited from tough thermally stable PTFE fibre yarn.

This yarn is impregnated with densified particles of PTFE to generate extra lubrication.

The packing is then cleansed of all organic matter and volatile content. Lionpak® 2100 is WRAS approved for use with hot and cold potable water at up to 85 °C (185 °F). A cost effective alternative without WRAS approval is also available, please download the Lionpak® 2101 datasheet for full details and specification.

Product features

- High purity, with excellent chemical resistance

- Long life valve sealing with minimum maintenance

- Clean and highly conformable for ease of fitting

Typical applications

The purity of Lionpak® 2100 allows it to be used as a valve packing for potable water applications. It is also suitable for slow speed pumps handling chemicals.

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 1 MPa / 100 bar (145 psi)

- Maximum shaft speed: 4 m/s (787 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 5 MPa / 50 bar (725 psi)

- Maximum rod speed: 0.5 m/s (98 fpm)

Chemical properties

Compatible with media in the range of pH 0-14 including corrosive acids and alkalis but excluding molten alkali metals, fluorine compounds and aqua regia.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″ ) in boxes containing 8 m (26′ 3” ) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

WRAS approved for use with hot and cold potable water at up to 85 °C (185 °F).

A specialised PTFE based packing that conforms to FDA and EU standards for cleanliness.

Lionpak® 2102 is a specialised braided packing from high performance, pure and dry expanded PTFE yarn with highly refined mineral filler particles, which are non-toxic and contain no lubricants or additives.

Lionpak® 2102 conforms to FDA and EU 1935/2004 standards for cleanliness.

Product features

- A dense, flexible and high purity packing with high cleanliness conforming to FDA and EU 1935/2004 standards

- Excellent chemical resistance with a high degree of dimensional stability

- Enhanced heat transfer properties

- Highly conformable for ease of fitting and with very low coefficient of friction

- Long life valve sealing with minimum maintenance

Typical applications

Slow speed centrifugal and reciprocating pumps and other rotary equipment as well as different types of valve, in applications where hygiene and the low friction characteristics of pure PTFE are required. It is also suitable for use with potable water, foodstuffs and pharmaceutical products.

Performance

Valve Stem Duties

- Maximum operating temperature: + 280 °C (+ 536 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 280 °C (+ 536 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 5 m/s (984 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 280 °C (+ 536 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 0.5 m/s (98 fpm)

Chemical properties

Resistant to chemicals in the range of pH 0-14, excluding strong oxidisers, molten alkali metals and fluorine compounds.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) or in coil form by the metre / foot or kilogram / pound

- Also supplied as split preformed rings and sets

Approvals & certifications

Conforms to:

- FDA 21 CFR 170.39

- EU regulation 1935/2004

100 % GFO yarn packing that is highly versatile and adds a new dimension to reliability and performance.

Formerly known as Fluograf, Lionpak® 2300 is a 100 % GFO yarn packing that is highly versatile and adds a new dimension to reliability and performance.

Made totally from WL Gore & Associates’ highly developed GFO yarn – combining the benefits of ePTFE, graphite and high temperature lubricants – this cross-plaited packing offers the ideal balance between density, resilience, strength and durability.

A cost effective alternative without WRAS approval is also available, please download Lionpak® 2302 datasheet for full details and specification.

Product features

- Extended service life – by up to 400 % in harsh environments

- Well proven with aggressive media

- High thermal conductivity for cool running

- Low coefficient of friction and minimal shaft wear

- Very good start-up and emergency running characteristics

- Non-hardening

Typical applications

Valves and pumps handling aggressive chemical media in the petrochemical, pulp and paper, power generation and metallurgical sectors – as well as potable water, and steam at up to 260 °C (500 °F).

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 8 MPa / 80 bar (1160 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148°F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 22 m/s (4331 fpm)

- Please contact us for duties up to 28 m/s (5512 fpm).

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 8 MPa / 80 bar (1160 psi)

- Maximum rod speed: 1 m/s (197 fpm)

- More severe duties can be sealed with specially designed arrangements.

Chemical properties

Compatible with chemicals in the range of pH 0-14, including steam, but excluding strong oxidising agents such as aqua regia, fuming nitric acid, oleum and molten alkali metals.

How supplied

- All popular square sections from 3 mm (1/8”) to 25 mm (1”) in boxes containing 8 m (26’ 3”) or in spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

WRAS approved for use with potable water up to 85 °C (185 °F).

A reliable packing based on graphite and PTFE yarn with silicone free lubrication.

Formerly known as Liongraf, Lionpak® 2303 is a highly reliable pump and valve packing based on graphite and PTFE yarn that is thermally stabilised then lubricated with a silicone-free compound.

Sections of 6.5 mm (1/4”) square and above are of cross-plaited construction; sections below 6.5 mm are plaited.

Product features

- Strong, durable and extrusion resistant

- Reliable over a wide range of duties

- Excellent chemical resistance

- Low friction with high thermal conductivity

Typical applications

Widely regarded as an economical packing for universal application and the reduction of stockholding requirements. Well proven in the petrochemical, power generation, marine and metallurgical sectors, and by pump and valve manufacturers for OEM installation. It is suitable for duties with steam, condensate, effluents, fuels and oils, acids, alkalis and chemical solutions.

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 12 MPa / 120 bar (1740 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 17.5 m/s (3445 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure (standard): 8 MPa / 80 bar (1160 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with chemicals in the range of pH 0-14, including corrosive fluids and solvents.

How supplied

- All popular square sections from 3 mm (1/8”) to 25 mm (1”) in boxes containing 8 m (26’ 3”) or in spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

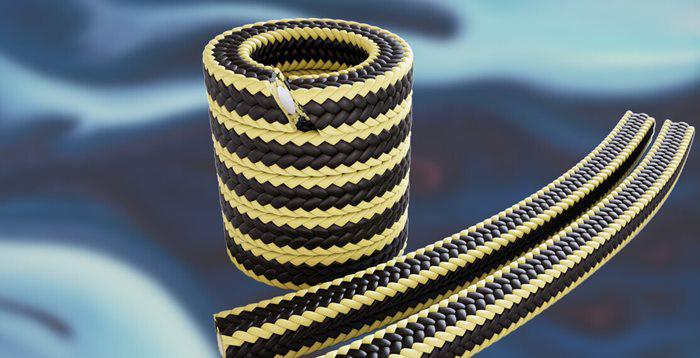

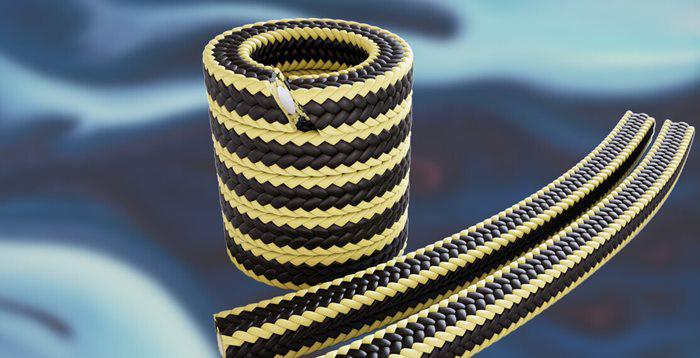

Tough, high performance packing with an elastomer core and WRAS approval for use with cold and hot potable water up to 85 °C.

Formerly known as Hornet, Lionpak® 2500 is a high performance packing that absorbs the eccentric action of worn shafts, spindles and bearings. It has a central core of temperature resistant elastomer.

This square sectioned packing is cross-plaited with tough aramid fibres at the corners to resist abrasion and wear. PTFE / graphite yarn at the centre of each side dissipates heat and presents a low friction face to the shaft or spindle.

A cost effective alternative without WRAS approval is also available, please download Lionpak® 2503 datasheet for full details and specification.

Product features

- Excellent abrasion resistance

- Superior compression and recovery characteristics with out-of-true shafts and spindles

- Excellent extrusion resistance

- Low shaft wear

- The high density elastomeric core provides resilience and resistance to high working pressures, and can absorb the vibration and eccentric movement created by worn running surfaces

Typical applications

- Valves and pumps handling abrasive and aggressive slurries in pulp and paper mills, petrochemical plants, sewage works, metallurgical plants and china clay works

- Also suitable for potable water and steam

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range of pH 2-13, including water, steam, fuels, oils, solvents, waxes and mild acids and alkalis.

How supplied

- All popular square sections from 5 mm (3/16”) to 25 mm (1”) in boxes containing 8 m (26’ 3”) or in spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

WRAS approved for use with cold and hot potable water up to 85 °C (185 °F).

PTFE / aramid packing for abrasion resistance with low friction for pumps and valves.

Lionpak® 2501 is a dense braided combination packing, with tough aramid yarn at the corners, PTFE yarn at the faces, and a strong core of extruded and expanded PTFE cord.

The aramid yarn is impregnated with an anti-friction fluoropolymer dispersion and a break-in lubricant, while the PTFE faces are treated with a high temperature resistant and inert lubricant.

Product features

- Dense construction that offers excellent sealability

- Aramid corners enhance long life in harsh plunger pump applications

- Expanded PTFE core provides improved compressibility and responsiveness, compared to the aramid core typically used on similar products

- PTFE faces provide low friction and low-wear running on shafts

Typical applications

Centrifugal, reciprocating and plunger pumps (particularly dosing pumps), valves, reactors, autoclaves and agitators. It can also be used as a replacement for traditional lip seals in certain applications. Suitable for use with ammonia, urea and carbamate condensate in fertiliser plant, pigments, dyestuffs, paints, amide, detergents, hydrazine, trisodium phosphate, sodium hexametaphosphate and slurries.

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range of pH 1-13.

How supplied

- All popular square sections from 6.5 mm (1/4“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

PTFE / graphite / aramid packing for abrasion resistance and cool running for pumps and valves.

Lionpak® 2502 is a specialised product which is a combination packing, with tough but smooth aramid fibre yarns at the corners, ePTFE / graphite fibre yarn at the faces, and a core of high density extruded and expanded PTFE cord.

This product is also available with an aramid core for higher pressure duties such as reciprocating pumps, please contact us for further details.

Product features

- PTFE/graphite faces offer excellent heat dissipation for cool running

- Aramid fibre corners withstand the rigours of plunger pump applications

- Aramid yarn is impregnated with fluoropolymer dispersion to enhance sealability, and a break-in lubricant to reduce friction

- PTFE core provides resistance to high working pressure

Typical applications

- With its dense construction and excellent sealability, this packing is used for chemical processing duties with pumps, valves, reactors, autoclaves, agitators and mixers.

- It is suitable for use with ammonia and carbamate solutions, hydrazine, trisodium phosphate, sodium hexametaphosphate, black and green liquor, chemical slurries, paper pulp, contaminated water and molasses.

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 20 MPa / 200 bar (2900 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range of pH 1-13.

How supplied

- All popular square sections from 6.5 mm (1/4“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

PTFE / graphite / fluoropolymer packing for industrial water duties.

Lionpak® 2504 is a specialised product which is a combination packing, duplex-braided packing. It comprises red fluoropolymer-based yarn and expanded PTFE intimately bonded with graphite yarn.

Product features

- A dense packing with a high degree of resilience, incorporating a break-in lubricant

- Both yarns are highly lubricated during manufacture; the red fluoropolymer-based yarn releases lubricant on inside diameter when packing is bent around the shaft

- This lubrication system provides very smooth start-up for pumps, plus long service life with low friction properties to safeguard shafts and sleeves from wear

- Graphite content aids heat dissipation to further extend the service life

Typical applications

- Dynamic and static duties, including pumps, valves, mixers and reactors, across many industrial sectors. It is recommended for cooling water pumps and condensate extraction systems.

- Also suitable for use with demineralised water, raw water, hydrocarbons, paints, synthetic resins, emulsions, viscous slurries, and many other general industrial media

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F);

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure (standard): 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range of pH 3-14.

How supplied

- All popular square sections from 3 mm (1/8“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

PTFE / carbon yarn packing for frequently operated control valves.

Lionpak® 2505 is a state-of-the-art gland packing especially developed for hard-working control valves.

This packing operates efficiently under arduous operating conditions where high resilience, high mechanical strength and high tensile strength are required.

The core of the packing is high strength carbon yarn, heavily lubricated with a special fluoropolymer dispersion and also treated with an inorganic passive corrosion inhibitor. The outer jacket is braided from pure PTFE yarn, lubricated with a PTFE suspensoid.

Product features

- Construction provides optimum leakage control in hard-working control valves

- Mechanically and thermally stable

- Very high recovery factor

- PTFE suspensoid acts as a blocking agent

- Dissipates heat without chemical hardening

- Easy to install, with smooth removal at shutdown

Typical applications

- Control valves and plug valves – especially those that are frequently operated

- Suitable for use with hydrocarbons, petrochemicals, superheated steam, saturated steam, organic/inorganic chemicals, acids and alkalis, solvents, amides, fuel oil, lubricating oil, dyestuffs, paints, and synthetic resins

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 30 MPa / 300 bar (4351 psi)

Chemical properties

Compatible with media in the range of pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 6.5 mm (1/4“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

PTFE / graphite and carbon packing for excellent abrasion and chemical resistance.

Lionpak® 2506 is an enhanced braided packing of expanded PTFE with high quality graphite entrapped in the porous structure of the PTFE resin and with tough carbon fibres at the corners to resist abrasion with minimal shaft wear.

The product is further lubricated with molybdenum disulphide (MoS2).

Product features

- A dense packing offering a high degree of dimensional stability

- The graphite provides heat dissipation to enhance the product’s long and efficient working life, which is also improved by the excellent thermal conductivity of molybdenum disulphide

- Molybdenum disulphide provides good chemical resistance and enhances high speed rotary operations by minimizing friction and wear

- The carbon fibre at the corners provides excellent abrasion resistance particularly in chemical slurries

- The product construction enables the packing to safeguard shaft/shaft sleeves from wear and erosion

Typical applications

- Centrifugal and reciprocating pumps, valves, large diameter shafts, reactor vessels, agitators, mixers and autoclaves, suitable for duties with acids and alkalis of any concentration, phosphoric acid, hydrocarbons, solvents, raw water, demineralised water, condensate and cooling water

- Also suitable for all types of slurries particularly chemical slurries, effluent, sewage as well as caustic and industrial water

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 22 m/s (4331 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Resistant to chemicals in the range pH 0-14, excluding strong oxidisers, molten alkali metals and fluorine compounds.

How supplied

- All popular square sections from 6.5 mm (1/4“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

Tough, high performance aramid packing resistant to chemicals at high temperature and with WRAS approval.

Formerly known as Duramid, Lionpak® 3200 is a tough, high performance packing, cross-plaited from texturised aramid yarns.

Each yarn is uniformly impregnated with PTFE dispersion and a silicone-based lubricant that resists chemical attack at high temperatures.

Lionpak® 3200 is WRAS approved for use with hot and cold potable water at up to 85 °C (185 °F). A cost effective alternative without WRAS approval is also available, please download the Lionpak® 3301 datasheet for full details and specification.

Product features

- Suitable for a very wide range of media

- Excellent abrasion resistance

- Long service life with minimal shaft wear

- Resilient and responsive in operation

Typical applications

- Valves and pumps handling abrasive and aggressive media in pulp and paper mills, petrochemical plants, power stations, metallurgical plants, sewage works and china clay works

- Also suitable for potable water, medium pressure steam, and hardening fluids such as tar and bitumen

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

- Please contact us for further information on higher speed duties.

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 1.5 m/s (295 fpm)

Chemical properties

Compatible with media in the range pH 2-13, including water, oils, solvents, medium strength acids and alkalis.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

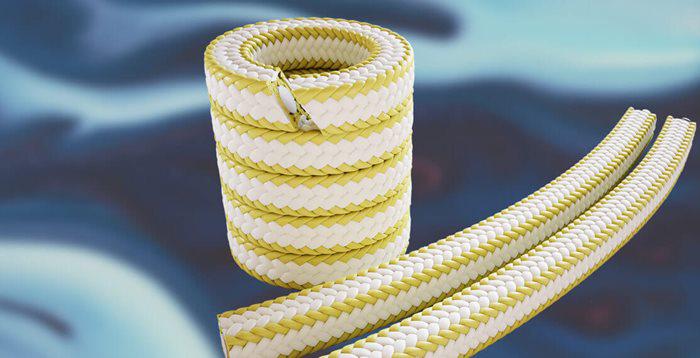

A specialised, high performance abrasion resistant ‘white’ gland packing.

Formerly known as Arasele, Lionpak® 3302 is a high performance abrasion-resistant ‘white’ gland packing offering minimal wear, braided from fine yarns of tough synthetic polymer fibre.

The yarns are texturised and impregnated uniformly and deeply with PTFE dispersion to a high concentration, before being braided over a central core of temperature resistant white elastomer.

A silicone-free, inert and colourless lubricant is incorporated during the manufacturing process to provide swift and easy running-in on dynamic duties.

Unlike traditional aramid-based packings which typically work at a maximum temperature + 250 °C (+ 482 °F), Lionpak® 3302 has a maximum operating temperature of + 285 °C (+ 545 °F).

Product features

- Kinder to shafts than traditional ‘yellow’ packings

- Can eliminate unnecessary wear under adverse operating conditions

- Excellent resistance to chemical and abrasive media

- Resists hydrolysis – ideal for steam, water and hot aqueous solutions

- Better thermal conductivity than most ‘white’ or ‘yellow’ packings

- Can absorb eccentric shaft / ram actions and thermal / pressure shocks and cycling

Typical applications

- Gland sealing on rotary or reciprocating pumps and valves that handle highly abrasive slurries or aggressive chemical solutions in the mineral, pulp and paper, wastewater and chemical processing industries

- It is also recommended for water, aqueous solutions and other media in processes where a clean white, non-staining gland packing is required

- Proves particularly effective in applications where its rubber core enables the packing to absorb the eccentric movement of shafts or rams that run out-of-true. Its construction can also provide the packing with swift recovery from thermal or pressure shocks and cycling.

Performance

Valve Stem Duties

- Maximum operating temperature: + 285 °C (+ 545 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 285 °C (+ 545 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 285 °C (+ 545 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 1.5 m/s (295 fpm)

Chemical properties

- Compatible with media in the range pH 0 -13, including steam, water, fuels, oils, solvents, acids and alkalis

- Note: this chemical resistance is better than that of traditional aramid-based packings

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

A high purity exfoliated graphite packing for valves and pumps.

Formerly known as Ribbonpak, Lionpak® 5100 is a high purity 98 % exfoliated graphite ribbon, plaited into a length-form packing for convenient on-site maintenance.

It is impregnated with James Walker®’s proprietary high temperature, graphite-based dispersion to enhance sealability.

A cost effective alternative is also available, please download the Lionpak 5101® datasheet for full details and specification.

Product features

- Excellent chemical resistance across an exceptionally wide temperature range

- Replaces moulded graphite sealing rings

- Flexible and compressible

- Easy to install – no special tools needed

- Reduces stockholding requirements

Typical applications

High speed rotary pumps handling water or slurry in pulp and paper processing. Also a general purpose valve stem packing for steam and chemical processing duties.

Performance

Valve Stem Duties

- Maximum operating temperatures:

- Steam: + 550 °C (+ 1022 °F)

- Oxidising conditions: + 450 °C (+ 842 °F)

- Non-oxidising conditions: + 850 °C (+ 1562 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperatures:

- Steam: + 550 °C (+ 1022 °F)

- Oxidising conditions: + 450 °C (+ 842 °F)

- Non-oxidising conditions: + 850 °C (+ 1562 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 25 m/s (4921 fpm)

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents. Negligible volatile content. Low in extractable trace impurities such as chloride and sulphur.

How supplied

- All popular square sections from 3 mm (1/8“) upwards, in boxes containing 8 m (26′ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

A high purity exfoliated graphite packing with Inconel reinforcement for valves.

Formerly known as Ribbonpak Type M, Lionpak® 5200 is a premium grade packing comprising exfoliated graphite fibre of high 98% carbon content, reinforced with Inconel® wires.

The graphite fibres are reinforced with fine Inconel wires and are dry having no additives or dispersion in order to maximise temperature capabilities.

Cost effective alternatives are also available, please download the Lionpak® 5201 and Lionpak® 5202 datasheets for full details and specification.

Product features

- Wire reinforcement enhances the mechanical strength of the packing to resist high pressures

- Exceptional temperature range

- Low friction and high thermal conductivity

- Easy to cut, shape and install

- Excellent chemical resistance

- Long service life with rotary or rising stem valves

- Conforms to Shell material specification MESC SPE 85/204

Typical applications

- Valves handling steam, condensate, fuel, oils, gases, chemicals, process water or effluent

- This product is widely used in petrochemical plants, refineries, power stations and steel mills

Performance

Valve Stem Duties

- Maximum operating temperatures:

- Steam: + 650 °C (+ 1202 °F)

- Oxidising conditions: + 450 °C (+ 842 °F)

- Non-oxidising conditions: + 1000 °C (+ 1832 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 30 MPa / 300 bar (4351 psi)

Chemical properties

- Compatible with media in the range pH 0-14, excluding strong oxidising agents. Negligible volatile content

- Low in extractable trace impurities such as chloride and sulphur

How supplied

- All popular square sections from 3 mm (1/8“) upwards, in boxes containing 8 m (26′ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

Shell MESC SPE 85/204

A premier quality graphite packing for valves with corrosion inhibitors.

Formerly known as Grafpak, Lionpak® 5300 is a dense, high strength packing of cross-plaited premier quality graphite filament yarns.

Treated with pure graphite before and after plaiting, and further treated with corrosion inhibitors.

A cost effective alternative is also available, please download the Lionpak® 5303 datasheet for full details and specification.

Product features

- Suitable for a wide range of aggressive media at elevated temperatures

- Low friction for low torque valve action

- Tough and resistant to fretting and extrusion

Typical applications

- Control valves and main stop valves on high temperature / pressure steam circuits at power stations, chemical plants, industrial services, and on marine installations

- Also suitable for duties with water, condensate, alkalis, acids, solvents and most chemicals

Performance

Valve Stem Duties

- Maximum operating temperatures:

- Steam: + 550 °C (+ 1022 °F)

- Oxidising conditions: + 550 °C (+ 1022 °F)

- Non-oxidising conditions: Significantly higher, please contact us for further details.

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure (typical): 15 MPa / 150 bar (2175 psi)

- Please contact us for details on higher pressure duties.

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 3 mm (1/8“) upwards, in boxes containing 8 m (26′ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

A specialised packing with carbon fibre strength, low friction and heat dissipation.

Lionpak® 5301 is a tough, high performance packing inter-braided from carbon fibre yarn.

It is impregnated with James Walker®’s proprietary graphite-based dispersion as a blocking agent, and a molybdenum based corrosion inhibitor.

Product features

- Strong, pliable and abrasion resistant

- Excellent heat dissipation and low friction qualities

- Inter-braiding plus blocking agent ensures leak-free construction

- Corrosion inhibitor prevents galvanic corrosion when used on applications with steam

Typical applications

Valves, pumps, mixers, reactors and agitators, handling steam, acids, alkalis, solvents, organic chemicals, gases and thermic fluids such as molten salt.

Performance

Valve Stem Duties

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 20 MPa / 200 bar (2900 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 450 °C (+842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Lionpak® 5301 may be suitable for higher pressures on certain reciprocating duties, please contact us for details.

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 3 mm (1/8“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A specialised graphite / carbon fibre packing for chemical and abrasion resistance.

Lionpak® 5302 is a specially developed packing that combines the advantages of soft expanded high purity 99 % graphite yarn with the toughness of carbon fibre yarn at its four corners.

It is impregnated with James Walker®’s proprietary, high temperature, graphite-based dispersion and an inorganic passive corrosion inhibitor.

Product features

- Recommended for applications at high working temperatures with corrosive media

- Good resistance to abrasion and wear

- Excellent dry-running capabilities that reduce the need for continuous water flushing

- Readily adapts to worn / pitted surfaces for smooth running under adverse mechanical conditions

- Corrosion inhibitor safeguards metallic interfaces from galvanic corrosion

Typical applications

- Pumps, valves, autoclaves, converters, mixers and reactors

- Suitable for duties with steam, acids and alkalis, hydrocarbons, fuel and lubricating oils, FCC catalyst and bottom slurry, hydrogen sulphide, sulphur dioxide, thermic fluid, and abrasive media such as ash slurry, fly ash water and sea water

Performance

Valve Stem Duties

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 6.5 mm (1/4“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A specialised carbon fibre packing for chemical resistance and low friction.

Lionpak® 5304 is a high grade packing of interlock-braided carbon fibre coated in PTFE.

The packing is thoroughly impregnated with James Walker®’s proprietary suspension to enhance sealability. This suspension is based on graphite, high temperature lubricant and corrosion inhibitors.

Product features

- Tough carbon fibre construction capable of handling steam, as well as the highly corrosive chemicals and abrasive media used in metallurgical processing plant

- Entrapping the suspension in a braided carbon fibre matrix increases lubrication as well as acting as a blocking agent

- Corrosion inhibitor safeguards metallic interfaces from galvanic corrosion

Typical applications

- Pumps, valves, reactors, agitators, mixers and other static or dynamic equipment in metallurgical processing and general industry

- Suitable for duties with steam and hot water, caustic chemicals (such as sodium hydroxide, potassium nitride, etc), acids and alkalis, organic chemicals, dry powder and thermic fluids

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 20 MPa / 200 bar (2900 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Lionpak® 5304 may be suitable for higher pressures on certain reciprocating duties, please contact us for details.

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 3 mm (1/8“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

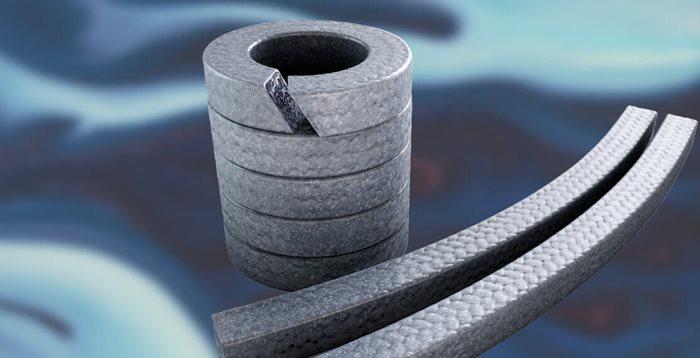

A mineral fibre packing for static sealing duties up to 1000 °C (1832 °F) constant.

Lionpak® 9601 is a special high-temperature compression packing for static duties.

It is manufactured from fibrous form of silica fibre with no metallic or ceramic content and impregnated with high temperature resistant additives as well as graphite based dispersion.

Product features

- Flexible packing that adapts well to groove corners: readily forms a circular section when required

- Ideal for application with knife edge gate valves

- Wear resistant with dry and hot abrasive slurries

- Graphite-based dispersion improves lubrication and also acts as a blocking agent to prevent leakage

- Resistant to high temperatures

Typical applications

- Recommended for autoclaves, converters and furnace doors. It can also be used on knife edge gate valves (valve bonnet sealing)

- Suitable for duties with ash slurries, chemical slurries, hot air, dry gases, superheated steam and saturated steam. This product may also be suitable for use on valves and pumps in certain applications; please contact us for further details

Performance

Static Duties

- Maximum operating temperature (constant): + 1000 °C (+ 1832 °F)

- Maximum operating temperature (intermittent): + 1100 °C (+ 2012 °F)

- Minimum temperature: – 50 °C (- 58 °F)

- Maximum static pressure dependent on application, please contact us for further details

Chemical properties

Compatible with media in the range pH 6-10.

How supplied

- All popular square sections from 3 mm (1/8”) to 50 mm (2”) in boxes containing 8 m (26’ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Health and safety considerations

- Average diameter of the mineral fibre used is over 6 μm (236 μin), which is considered non-hazardous to health, no protection for breathing, eye, hand or body is required by the World Health Organisation or European Union for the material’s normal handling, storage or use.

- For further details please contact us to request a copy of our Safety Data Sheet (SDS)

- Note that normal ceramic fibres, as often used in the manufacture of very high temperature compression packings, are around 3 μm (118 μin) in diameter, these much finer fibres are considered hazardous to health, with WHO and EU restrictions applied to the products that contain them.

A mineral fibre packing for high temperature static and dynamic sealing duties.

Lionpak® 9602 comprises an interlocked braid of fibrous form, inorganic refractory oxides – silica fibre with no metallic or ceramic content.

It is impregnated with anti-frictional graphite flake and James Walker®’s proprietary, high temperature, graphite-based dispersion. It also incorporates a metal corrosion inhibitor.

Product features

- Suitable for many high temperature duties

- Resistant to wear and abrasion

- Corrosion inhibitor safeguards metallic interfaces from galvanic corrosion

- Resistant to high temperatures

Typical applications

- Recommended for hydro-testing of heat exchangers; also for general duties with furnace and oven doors

- Suitable for duties with superheated steam and saturated steam, water, dyes, chemicals, non-oxidising liquids and gases

- This product is also suitable for use on valves and centrifugal pumps

Performance

Valve Stem Duties

- Maximum operating temperature: + 550 °C (+ 1022 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 8 MPa / 80 bar (1160 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 550 °C (+ 1022 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 10 m/s (1969 fpm)

Static Duties

- Maximum operating temperature: + 550 °C (+ 1022 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum static pressure dependent on application, please contact us for further details

Chemical properties

Compatible with media in the range pH 0-14.

How supplied

- All popular square sections from 3 mm (1/8“) to 50 mm (2″) in boxes containing 8 m (26′ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Health and safety considerations

- Average diameter of the mineral fibre used is over 6 μm (236 μin), which is considered non-hazardous to health. No protection for breathing, eye, hand or body is required by the World Health Organisation or European Union for the material’s normal handling, storage or use.

- For further details please contact us to request a copy of our Safety Data Sheet (SDS)

- Note that normal ceramic fibres, as often used in the manufacture of very high temperature compression packings, are around 3 μm (118 μin) in diameter. These much finer fibres are considered hazardous to health, with WHO and EU restrictions applied to the products that contain them.

Graphite moulded rings with outstanding qualities.

Lionpak® graphite moulded rings are high-efficiency, moulded graphite sealing rings, produced to precise density and size.

They are manufactured from expanded high purity flexible graphite foil with an oxidation inhibitor. They do not contain binders, elastomers or fillers.

The difference between the three model numbers is the purity of the graphite foil from which the rings are manufactured.

Product features

- Outstanding sealing performance over long adjustment-free periods

- Excellent chemical resistance

- Very wide temperature range

Typical applications

Valves and rotary equipment handling virtually any media. These rings are ideal for duties with high-temperature steam, demineralised water, heat transfer media, petroleum products, inorganic and organic acids, alkalis, hot waxes and oils.

Performance

Valve stem duties

- Maximum operating temperature in steam: + 650 °C (+ 1202 °F)

- Maximum operating temperature in oxidising conditions: + 500 °C (+ 932 °F)

- Maximum operating temperature in non-oxidising conditions: + 1000 °C (+ 1832 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Certain rotary equipment

- Dependant on application, please contact James Walker® for further details for rotary duties

Recommended ring densities

- For valve stem duties: 1.6 g / cm3 (SG 1.6)

- For rotary duties: 1.5 g / cm3 (SG 1.5)

- For special applications: mixture of ring densities

Material properties

- Compatible with media in the range pH 0 -14

- Sulphur content (typical): ≤ 300 ppm

- No loss of volatiles at high temperature

- Lower limiting temperatures apply when used with oxidising agents, e.g. nitric acid

- Thermal conductivity, ring of density 1.4 g / cm3: (SG 1.4): axial: 400 W / mK; radial: 6 W / mK

- Coefficient of friction to steel: 0.05

How supplied

- Precision moulded rings in endless form, or with single split or matched scarf-split halves. Sections 1.5 mm to 40 mm (1/16” to 19/16“); diameters 2 mm to 1200 mm (or 3/32” to 47 1/4“)

A longterm, high integrity sealing solution for control valves.

Supagraf® Control is an innovative compression packing that provides long-term, high integrity sealing for control valves. Its very low friction enhances the control accuracy of valves. This is a ‘best available technique’ product for reducing industry’s VOC fugitive emissions in line with the European Union’s IPPC Directive.

It is manufactured in exfoliated graphite, reinforced in a novel way with a non-metallic structure to provide additional strength and resistance to pressure and extrusion. An advanced lubricant system is incorporated to prevent the pick-up of graphite on valve stems.

Product features

- High integrity gland sealing for control valve stems: to well below 50 ppm fugitive emission level

- Long-term adjustment-free operation: over 100,000 stem strokes with emission levels below 50 ppmV

- Very low coefficient of friction for smooth and accurate valve action

- Reduced friction requirement to save on power consumption and enable smaller actuators to be used

Typical applications

- Designed for emission control – to better than 50 ppmV leak tightness – on control valves in systems handling fluid media such as hydrocarbon liquid fuels and gases, lubricating oils and hazardous process chemicals

- It is a long-term replacement for the PTFE V-type packings that can be readily damaged by ingress of dirt and other foreign particles to the gland area

Performance

Valve stem duties:

- Maximum operating temperature: Up to + 350 °C (+ 662 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure (standard): 25 MPa / 250 bar (3626 psi) – contact us for advice on use at higher pressures

Chemical properties

Compatible with media in the range of pH 1-14 excluding strong oxidising agents. The product has low volatile content.

How supplied

- All popular square sections from 3 mm (1/8“) upwards in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Non-standard square or rectangular sections made to order

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

- TA Luft/VDI 2440

- ISO 15848-1 Class BH, CC3

A high performance fugitive emission control packing for valves.

Supagraf® FE is third party tested to all known industry standards producing exceptional performance, 8 ppmV average emission level in API 622 3rd edition test with no adjustments. This is a cost effective fully braided packing manufactured in exfoliated high purity 98 % graphite, reinforced with Inconel® wire to provide additional strength and resistance to pressure and extrusion.

This packing incorporates a new generation cutting-edge lubrication system that not only helps to prevent the pick-up of graphite on valve stems but also provides ultra-low friction performance with advanced corrosion inhibiting properties.

Product features

- Third party verified emission control performance

- Suitable for both rotary as well as rising-stem valve application

- Ultra-low friction performance without graphite pick-up reducing the torque needed for efficient valve action

- Fire safe capability confirmed by third-party certification according to API 607 Edition 7 Fire Safety / ISO 10497:2010

- Suitable for use in valves from pressure Class 150 up to Class 1500 – please consult us for further advice and Class 2500 suitability

- Can mitigate the effects of stem judder and friction by helping to prevent graphite pickup or high spot friction on the valve stem, especially in applications with high rates of thermal cycling and dynamic stem movements

Typical applications

- Supagraf® FE is designed for harsh operating conditions where fugitive emissions from valves need to be reduced to well below 50 ppm

- Suitable for all types of valves performing arduous duties handling fluid media such as hydrocarbon liquid fuels and gases, lubricating oils and processing chemicals

- Also suitable for valves that handle dry gases and other fluids

Performance

Valve stem duties:

- Maximum operating temperature in oxidising conditions: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure (standard): 25 MPa / 250 bar (3626 psi) – contact us for advice on use at higher pressures

Chemical properties

Compatible with media in the range of pH 1-14 excluding strong oxidising agents. The product has negligible volatile content.

How supplied

- All popular square sections from 3 mm (1/8“) upwards in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Non-standard square or rectangular sections made to order

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

- ISO 15848-1:2015 Class BH (CO1)

- API 622 3rd Edition

- TA Luft VDI 2440 Rev. 07.2002

- Shell MESC SPE 85/204

- Shell specification SPE 77/312 Class AH Rev. 02.2019

- API 607 Edition 7 Fire Safety

Supagraf® H2 is a high performance, unique combination, valve stem packing set designed for hydrogen service.

This packing solution incorporates Supagraf® Premier, one of James Walker®’s top-of-the-range fugitive emission control packings that has a long track record of exceptional performance in valves handling hydrocarbon liquid fuels and gases, lubricating oils or processing chemicals including hydrogen.

The performance of Supagraf® Premier graphite packing rings are then enhanced by the use of precision machined carbon rings, inserted at the top and bottom of the stuffing box set and used as intermediary rings.

This product has been third party tested and is validated by James Walker® for use in hydrogen service.

Typical applications

Supagraf® H2 is designed specifically for the harsh operating conditions of all types of valves in hydrogen service where exceptional tightness, safety and extended dynamic sealing performance is required.

The product is also compatible with different blends of hydrogen and other liquid or gaseous media as well as hydrocarbons or chemicals.

Performance

Valve stem duties

- Maximum operating temperature in oxidising conditions: + 450 °C (+ 842 °F)

- Minimum Operating Temperature: – 253 °C (- 423 °F)

- Maximum System Pressure (Standard): 69 MPa / 690 bar (10000 psi)

Contact us for advice where operating conditions are outside these limits.

Approvals & certifications

Supagraf® H2 combination packing set has been 3rd party tested and certified for hydrogen service. The test regime has been adapted from ISO 15848-1 standard and modified with the use of 99 % hydrogen test media as opposed to ISO 15848-1 specified helium gas. The product has been tested at room temperature and to CO1 endurance class reaching class BH* leakage performance (with no adjustment).

The product has also been tested according to ISO 15848-1 standard (with helium test media) in configuration of Supagraf® Premier graphite rings with single bottom stuffing box machined carbon ring, achieving class BH tightness at CO1 endurance class and temperature range from – 196 °C [- 321 °F] up to + 400 °C [752 °F] (with no adjustment).

In addition, the stand-alone Supagraf® Premier packing set has been tested and certified to:

- ISO 15848-1 Class AH (fugitive emissions): Certified by ITIS BV at 69 MPa (static) with a five-ring set in a BSM valve. Emission level at 69 MPa / 690 bar (10,000 psi) was ≤ 5 ppmV

- API 622: average emission level of 10.5 ppmV, with a maximum of 37 ppmV over five thermal cycles and 1510 mechanical cycles

- TA Luft Rev 07.2002 requirements / VDI 2440

- Shell specification SPE 77/312 Class A, Rev 16.10.2002

- Shell specification SPE 77/312 Rev 06.2007: Class B rating with 47.4 MPa / 474 bar (6875 psi) helium in Class 2500 valve

- API 607 Edition 4 Fire Safety

- Base graphite material complies to Shell MESC SPE 85/204.

*Note: BH volumetric leak rate used for Hydrogen gas.

Chemical properties

Compatible with media in the range of pH 0-14 excluding strong oxidising agents. The product has negligible volatile content.

How supplied

As preformed graphite rings with a single split combined with precision machined carbon rings supplied endless or split in two matched halves with cut of 45 degrees. Product made to order to suit application requirements.

An ultrahigh temperature resistant packing suitable for critical valves handling high temperature media.

Supagraf® HT is one of James Walker®’s high performance packings suitable for critical valves handling various high temperature media such as molten salt used in solar, nuclear, chemical, energy storage, and hydrogen production industry sectors.

Premium grade unique and bespoke combination set construction comprising of high temperature mechanically stable intermediate and end ring DS Pro spacers supported by high purity graphite-based intermediate packing rings.

Graphite rings: High performance packing braided from high purity 98 % exfoliated dry graphite yarn with passive corrosion inhibitor, reinforced with fine Inconel wire and free from all other additives or dispersions in order to maximise temperature and corrosion resistance capabilities. Graphite base material conforms to Shell material specification MESC SPE 85/204.

DS Pro spacers: Precision cut spacers made of state-of-the-art material designed for electro-mechanical and thermo-mechanical applications with excellent resistance to heat and open flame up to 1000 °C (1832 °F). Excellent electrical insulation and high resistance to pressure as well as impervious to most chemicals such as molten salt. The product has improved dimensional stability at high temperatures, low water absorption and is asbestos free, ecologically safe and non-toxic. Typically of 2-3 mm thickness and in multiple layers, customised to valve stuffing box geometry and design.

Product features

- Exceptional high temperature resistance

- Excellent chemical resistance

- Corrosion resistance capabilities

- Inconel wire reinforcement enhances thermal expansion capabilities in high temperature cycles

- Low oxidation rate and long service life in high temperature applications

- Easy to install, remove and replace

- 3rd party tested in high temperature molten salt valve applications

- Suitable for both rotary as well as rising-stem valve applications from pressure Class 150 up to Class 600

- Please contact us for further advice for higher Class range suitability

Typical applications

Supagraf® HT is designed for chemically aggressive and abrasive operating conditions in all types of valves, where resistance to high temperature media such as molten salt as well as extended dynamic sealing performance is required.

Performance

Valve stem duties

- Maximum operating temperature: Up to + 650 °C (+ 1202 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure (standard): 10 MPa / 100 bar (1450 psi) – contact us for advice on use at higher pressures

Chemical properties

Compatible with media in the range of pH 0-14 excluding strong oxidising agents. The product has negligible volatile content.

How supplied

- As preformed graphite rings with a single split combined with precision cut DS Pro spacers supplied endless or split in two matched halves

- Product made to order to suit application requirements

A graphite yarn compression packing designed for valves in oxygen service.

Supagraf® OX has been developed specifically for valve services with gaseous and liquid oxygen, to provide safe operation and low emission rates. This valve stem packing is manufactured in a clean room environment, from yarn to finished product. It comprises high purity flexible graphite yarn treated with oxidation inhibitors. The yarns are individually reinforced with Inconel® 600 wire mesh.

Product features

- Manufactured in a clean room environment, from yarn to finished product

- High purity flexible graphite yarn treated with oxidation inhibitors

- Yarns individually reinforced with Inconel® 600 wire mesh

Typical applications

- Supagraf® OX is designed for valves handling gaseous or liquid oxygen

- For applications involving media other than oxygen, please contact us for further advice

- Supagraf® OX is NOT suitable for use with control valves where fine adjustment is required, as this is a dry product that does not contain a lubricant package

Performance

For gaseous oxygen service up to + 60 °C (+ 140 °F):

- Maximum oxygen pressure 44 MPa / 440 bar (6382 psi)

For gaseous oxygen service from + 60 °C (+ 140 °F) up to + 300 °C (+ 572 °F):

- Maximum oxygen pressure 25 MPa / 250 bar (3626 psi)

For liquid oxygen service:

- Limit service pressure to 45 MPa / 450 bar (6527 psi)

How supplied

- All popular square sections from 3 mm to 25 mm (1/8” to 1″) in boxes containing 8 m (26′ 3″), or in coil form by the metre / foot or kilogram / pound

- Also supplied as split preformed rings and sets

Approvals & certifications

- BAM certified

- Shell MESC SPE 85/204

- Shell MESC SPE 77/303

Our worldbeating fugitive emission control packing for valves, third party tested to all known industry standards.

Supagraf® Premier is manufactured in exfoliated high purity 98 % graphite, reinforced in a novel way to provide additional strength and resistance to pressure and extrusion. It incorporates an advanced lubricant system that prevents the pick-up of graphite on valve stems and produces exceptional performance, 10.5 ppmV average emission level in API 622 2nd edition test with no adjustments.

Product features

- Third party verified emission control performance

- Suitable for both rotary as well as rising-stem applications

- Low friction performance without graphite pick-up reducing the torque needed for efficient valve action

- Fire safe capability confirmed by third-party certification according to API 607 Edition 4 Fire Safety

Typical applications

Supagraf® Premier is designed for harsh operating conditions where fugitive emissions from all types of valves need to be reduced to well below 50 ppm. This packing is well proven and widely used in systems handling fluid media such as hydrocarbon liquid fuels and gases, lubricating oils and processing chemicals.

Performance

Valve stem sealing duties:

- Maximum operating temperature in oxidising conditions: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi) – consult us for advice on use at higher pressures

- Certified pressure in BSM valve: 69 MPa / 690 bar (10000 psi)

How supplied

- All popular square sections from 3 mm (1/8“) upwards in boxes containing 8 m (26′ 3”),in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Non-standard square or rectangular sections made to order

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

- ISO 15848-1 Class AH

- API 622 2nd Edition

- TA Luft / VDI 2440 Rev. 07.2002

- Shell MESC SPE 85/204

- Shell specification SPE 77/312 Class A

- Shell specification SPE 77/312 Class B

- API 607 Edition 4 Fire Safety