Walkersele® Radial Lip Seals – Specials

Within our Walkersele® family we have highly-developed materials and designs that offer exceptional benefits to specific sectors of industry.

In addition, if you cannot find the exact radial lip seal you require to meet specific operational parameters, James Walker® Technology Centre will custom design, prototype, test and manufacture a new seal in partnership with your own engineering teams.

Walkersele® Aflas

FEPM-based elastomer for aggressive media

- Long-term operation with hot aggressive chemicals

- Resists bleaching agents used in dewatering presses in pulp and paper plant

- Suitable for duties in radioactive environments

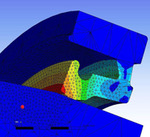

Walkersele® customised designs

A speciality of James Walker®’s sealing experts

- New seals developed and tested for OEMs

- Using state-of-the-art technology

- Backed by unparalleled sealing expertise

Walkersele® SpringSafe

Positive spring retention

- Ensures spring is properly located at installation

- Reduces the possibility of spring becoming dislodged to create secondary damage if shaft or bearing exceeds normal operating limits

- Allows effective spring coil action

Walkersele® TBMS

Positive spring retention

- Ensures spring is properly located at installation

- Reduces the possibility of spring becoming dislodged to create secondary damage if shaft or bearing exceeds normal operating limits

- Allows effective spring coil action