Packing for pumps

Finding solutions to customer challenges

Although today’s compression packing products follow a very similar form to those created by our founder in the late 1800’s, the development of new fibres and additive packages means that their performance is a world away from that of their early ‘ancestors’.

Today’s packings are capable of running at higher speeds, lubrication free, at higher temperatures and providing a better, longer lasting seal than ever before and as a result are still the preferred option for pump shaft sealing by many engineers.

With over 30 different packing types in the James Walker® Lionpak® range, there is a product for every application, from food and pharmaceutical safe PTFE-based dry packings to heavily lubricated graphite or aramid-fibre packings which are ideal for duties involving highly abrasive media.

In applications where predictable controlled leakage is acceptable, then modern packings provide an excellent, cost-effective sealing option that is both easy to install, maintain and replace within standard maintenance schedules. Correctly specified, installed, monitored and maintained, packing is a very reliable sealing option for pump shafts.

It all starts with getting the right packing in the first place; Size, Temperature, Application, Media, Pressure and Shaft speed – correctly identify these parameters and your packing supplier should be able to provide the ideal product for the job.

Next, examine the pump components for excessive wear, damage, being out of tolerance or having contact surfaces of the wrong hardness or surface finish for effective use with packing. Although compression packing is more tolerant of worn or out of true components than many other sealing options, it can’t work miracles. Don’t blame leakage on packing if your equipment is past its best!

By now you should be ready to install the correct packing into a pump that is in good condition. Carefully adhere to the instructions provided by both pump and packing manufacturers and you will have a reliable, cost-effective and long-term seal ready to provide trouble-free performance.

Of course, James Walker® experts are available to guide you through any part of this process, or will happily consult on troubleshooting sealing problems you may be experiencing. Fitting guides are also available for all packing applications.

Cross plaited thermally stable PTFE packing for pumps, where exceptional chemical resistance is required.

Formerly known as Fluolion® Filament L, Lionpak® 2200 is a cross-plaited packing made from tough thermally stable PTFE fibre yarn. This yarn is impregnated with densified particles of PTFE to generate additional lubrication.

A cost effective alternative is available, please download the Lionpak® 2201 datasheet for full details and specification.

Product features

- Excellent chemical resistance

- High performance sealing in valve and pump applications

- Long and efficient working life with minimum maintenance requirements

- Clean and highly conformable for ease of fitting

Typical applications

This high performance packing is used where its exceptional chemical resistance is required in valves, rotary equipment and reciprocating plant.

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 10 m/s (1969 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 1 m/s (197 fpm)

Chemical properties

Compatible with media in the range of pH 0-14, including corrosive acids and alkalis but excluding molten alkali metals and fluorine compounds and aqua regia.

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A specialised PTFE based diagonally braided packing, filled with refined mineral filler particles that conforms to FDA standards for cleanliness.

Lionpak® 2202 is a specialised diagonally braided packing from high performance, pure expanded PTFE yarn filled with highly refined mineral filler particles and treated with FDA-conforming mineral oil.

Product features

- A dense, flexible and high purity packing with high cleanliness conforming to FDA standards

- Excellent chemical resistance with a high degree of dimensional stability

- High performance sealing in valve and pump applications

- Enhanced heat transfer properties

- Highly conformable for ease of fitting and with very low coefficient of friction

- Long and efficient working life with minimal shaft wear and maintenance issues

Typical applications

Recommended for both static and dynamic operations with centrifugal and reciprocating pumps, valves, mixers, reactors, agitators, dryers and air compressors, in applications where hygiene and the low friction characteristics of pure PTFE are required. It is also suitable for use with potable water, foodstuffs and pharmaceutical products.

Performance

Valve stem duties

- Maximum operating temperature: + 280 °C (+ 536 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 280 °C (+ 536 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 12 m/s (2362 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 280 °C (+ 536 °F)

- Minimum operating temperature: – 100 °C (- 148 °F);

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 1 m/s (197 fpm)

Chemical properties

Resistant to chemicals in the range of pH 0-14, excluding strong oxidisers, molten alkali metals and fluorine compounds.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) or in coil form by the metre / foot or kilogram / pound

- Also supplied as split preformed rings and sets

Approvals & certifications

Conforms to:

- FDA 21 CFR 170.39

100 % GFO yarn packing that is highly versatile and adds a new dimension to reliability and performance.

Formerly known as Fluograf, Lionpak® 2300 is a 100 % GFO yarn packing that is highly versatile and adds a new dimension to reliability and performance.

Made totally from WL Gore & Associates’ highly developed GFO yarn – combining the benefits of ePTFE, graphite and high temperature lubricants – this cross-plaited packing offers the ideal balance between density, resilience, strength and durability.

A cost effective alternative without WRAS approval is also available, please download Lionpak® 2302 datasheet for full details and specification.

Product features

- Extended service life – by up to 400 % in harsh environments

- Well proven with aggressive media

- High thermal conductivity for cool running

- Low coefficient of friction and minimal shaft wear

- Very good start-up and emergency running characteristics

- Non-hardening

Typical applications

Valves and pumps handling aggressive chemical media in the petrochemical, pulp and paper, power generation and metallurgical sectors – as well as potable water, and steam at up to 260 °C (500 °F).

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 8 MPa / 80 bar (1160 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148°F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 22 m/s (4331 fpm)

- Please contact us for duties up to 28 m/s (5512 fpm).

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 8 MPa / 80 bar (1160 psi)

- Maximum rod speed: 1 m/s (197 fpm)

- More severe duties can be sealed with specially designed arrangements.

Chemical properties

Compatible with chemicals in the range of pH 0-14, including steam, but excluding strong oxidising agents such as aqua regia, fuming nitric acid, oleum and molten alkali metals.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) or in spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

WRAS approved for use with potable water up to 85 °C (185 °F).

A reliable packing based on graphite and PTFE yarn with silicone free lubrication.

Formerly known as Liongraf, Lionpak® 2303 is a highly reliable pump and valve packing based on graphite and PTFE yarn that is thermally stabilised then lubricated with a silicone-free compound.

Sections of 6.5 mm (1/4“) square and above are of cross-plaited construction; sections below 6.5 mm are plaited.

Product features

- Strong, durable and extrusion resistant

- Reliable over a wide range of duties

- Excellent chemical resistance

- Low friction with high thermal conductivity

Typical applications

Widely regarded as an economical packing for universal application and the reduction of stockholding requirements. Well proven in the petrochemical, power generation, marine and metallurgical sectors, and by pump and valve manufacturers for OEM installation. It is suitable for duties with steam, condensate, effluents, fuels and oils, acids, alkalis and chemical solutions.

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 12 MPa / 120 bar (1740 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 17.5 m/s (3445 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure (standard): 8 MPa / 80 bar (1160 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with chemicals in the range of pH 0-14, including corrosive fluids and solvents.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) or in spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

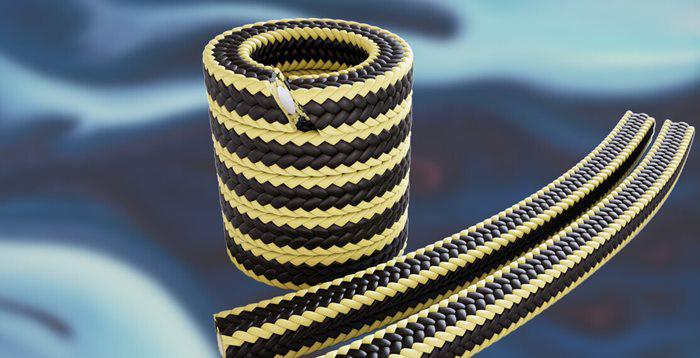

Tough, high performance packing with an elastomer core and WRAS approval for use with cold and hot potable water up to 85 °C.

Formerly known as Hornet, Lionpak® 2500 is a high performance packing that absorbs the eccentric action of worn shafts, spindles and bearings. It has a central core of temperature resistant elastomer.

This square sectioned packing is cross-plaited with tough aramid fibres at the corners to resist abrasion and wear. PTFE / graphite yarn at the centre of each side dissipates heat and presents a low friction face to the shaft or spindle.

A cost effective alternative without WRAS approval is also available, please download Lionpak® 2503 datasheet for full details and specification.

Product features

- Excellent abrasion resistance

- Superior compression and recovery characteristics with out-of-true shafts and spindles

- Excellent extrusion resistance

- Low shaft wear

- The high density elastomeric core provides resilience and resistance to high working pressures, and can absorb the vibration and eccentric movement created by worn running surfaces

Typical applications

- Valves and pumps handling abrasive and aggressive slurries in pulp and paper mills, petrochemical plants, sewage works, metallurgical plants and china clay works

- Also suitable for potable water and steam

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range of pH 2-13, including water, steam, fuels, oils, solvents, waxes and mild acids and alkalis.

How supplied

- All popular square sections from 5 mm (3/16“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) or in spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

Approvals & certifications

WRAS approved for use with cold and hot potable water up to 85 °C (185 °F).

PTFE / graphite / fluoropolymer packing for industrial water duties.

Lionpak® 2504 is a specialised product which is a combination packing, duplex-braided packing. It comprises red fluoropolymer-based yarn and expanded PTFE intimately bonded with graphite yarn.

Product features

- A dense packing with a high degree of resilience, incorporating a break-in lubricant

- Both yarns are highly lubricated during manufacture; the red fluoropolymer-based yarn releases lubricant on inside diameter when packing is bent around the shaft

- This lubrication system provides very smooth start-up for pumps, plus long service life with low friction properties to safeguard shafts and sleeves from wear

- Graphite content aids heat dissipation to further extend the service life

Typical applications

- Dynamic and static duties, including pumps, valves, mixers and reactors, across many industrial sectors. It is recommended for cooling water pumps and condensate extraction systems.

- Also suitable for use with demineralised water, raw water, hydrocarbons, paints, synthetic resins, emulsions, viscous slurries, and many other general industrial media

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F);

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure (standard): 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range of pH 3-14.

How supplied

- All popular square sections from 3 mm (1/8“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

PTFE / graphite and carbon packing for excellent abrasion and chemical resistance.

Lionpak® 2506 is an enhanced braided packing of expanded PTFE with high quality graphite entrapped in the porous structure of the PTFE resin and with tough carbon fibres at the corners to resist abrasion with minimal shaft wear.

The product is further lubricated with molybdenum disulphide (MoS2).

Product features

- A dense packing offering a high degree of dimensional stability

- The graphite provides heat dissipation to enhance the product’s long and efficient working life, which is also improved by the excellent thermal conductivity of molybdenum disulphide

- Molybdenum disulphide provides good chemical resistance and enhances high speed rotary operations by minimising friction and wear

- The carbon fibre at the corners provides excellent abrasion resistance particularly in chemical slurries

- The product construction enables the packing to safeguard shaft/shaft sleeves from wear and erosion

Typical applications

- Centrifugal and reciprocating pumps, valves, large diameter shafts, reactor vessels, agitators, mixers and autoclaves, suitable for duties with acids and alkalis of any concentration, phosphoric acid, hydrocarbons, solvents, raw water, demineralised water, condensate and cooling water

- Also suitable for all types of slurries particularly chemical slurries, effluent, sewage as well as caustic and industrial water

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 22 m/s (4331 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Resistant to chemicals in the range pH 0-14, excluding strong oxidisers, molten alkali metals and fluorine compounds.

How supplied

- All popular square sections from 6.5 mm (1/4“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

Tough, high performance aramid packing resistant to chemicals at high temperature and with WRAS approval.

Formerly known as Duramid, Lionpak® 3200 is a tough, high performance packing, cross-plaited from texturised aramid yarns.

Each yarn is uniformly impregnated with PTFE dispersion and a silicone-based lubricant that resists chemical attack at high temperatures.

Lionpak® 3200 is WRAS approved for use with hot and cold potable water at up to 85 °C (185 °F). A cost effective alternative without WRAS approval is also available, please download the Lionpak® 3301 datasheet for full details and specification.

Product features

- Suitable for a very wide range of media

- Excellent abrasion resistance

- Long service life with minimal shaft wear

- Resilient and responsive in operation

Typical applications

- Valves and pumps handling abrasive and aggressive media in pulp and paper mills, petrochemical plants, power stations, metallurgical plants, sewage works and china clay works

- Also suitable for potable water, medium pressure steam, and hardening fluids such as tar and bitumen

Performance

Valve Stem Duties

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

- Please contact us for further information on higher speed duties.

Reciprocating Pumps and Rams

- Maximum operating temperature: + 250 °C (+ 482 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 1.5 m/s (295 fpm)

Chemical properties

Compatible with media in the range pH 2-13, including water, oils, solvents, medium strength acids and alkalis.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

A specialised, high performance abrasion resistant ‘white’ gland packing.

Formerly known as Arasele, Lionpak® 3302 is a high performance abrasion-resistant ‘white’ gland packing offering minimal wear, braided from fine yarns of tough synthetic polymer fibre.

The yarns are texturised and impregnated uniformly and deeply with PTFE dispersion to a high concentration, before being braided over a central core of temperature resistant white elastomer.

A silicone-free, inert and colourless lubricant is incorporated during the manufacturing process to provide swift and easy running-in on dynamic duties.

Unlike traditional aramid-based packings which typically work at a maximum temperature + 250 °C (+ 482 °F), Lionpak® 3302 has a maximum operating temperature of + 285 °C (+ 545 °F).

Product features

- Kinder to shafts than traditional ‘yellow’ packings

- Can eliminate unnecessary wear under adverse operating conditions

- Excellent resistance to chemical and abrasive media

- Resists hydrolysis – ideal for steam, water and hot aqueous solutions

- Better thermal conductivity than most ‘white’ or ‘yellow’ packings

- Can absorb eccentric shaft / ram actions and thermal / pressure shocks and cycling

Typical applications

- Gland sealing on rotary or reciprocating pumps and valves that handle highly abrasive slurries or aggressive chemical solutions in the mineral, pulp and paper, wastewater and chemical processing industries

- It is also recommended for water, aqueous solutions and other media in processes where a clean white, non-staining gland packing is required

- Proves particularly effective in applications where its rubber core enables the packing to absorb the eccentric movement of shafts or rams that run out-of-true. Its construction can also provide the packing with swift recovery from thermal or pressure shocks and cycling.

Performance

Valve Stem Duties

- Maximum operating temperature: + 285 °C (+ 545 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 285 °C (+ 545 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 285 °C (+ 545 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 1.5 m/s (295 fpm)

Chemical properties

- Compatible with media in the range pH 0 -13, including steam, water, fuels, oils, solvents, acids and alkalis

- Note: this chemical resistance is better than that of traditional aramid-based packings

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

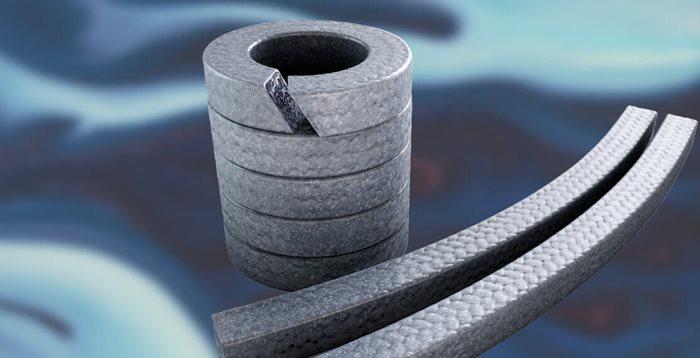

A high purity exfoliated graphite packing for valves and pumps.

Formerly known as Ribbonpak, Lionpak® 5100 is a high purity 98 % exfoliated graphite ribbon, plaited into a length-form packing for convenient on-site maintenance.

It is impregnated with James Walker®’s proprietary high temperature, graphite-based dispersion to enhance sealability.

A cost effective alternative is also available, please download the Lionpak 5101® datasheet for full details and specification.

Product features

- Excellent chemical resistance across an exceptionally wide temperature range

- Replaces moulded graphite sealing rings

- Flexible and compressible

- Easy to install – no special tools needed

- Reduces stockholding requirements

Typical applications

High speed rotary pumps handling water or slurry in pulp and paper processing. Also a general purpose valve stem packing for steam and chemical processing duties.

Performance

Valve Stem Duties

- Maximum operating temperatures:

- Steam: + 550 °C (+ 1022 °F)

- Oxidising conditions: + 450 °C (+ 842 °F)

- Non-oxidising conditions: + 850 °C (+ 1562 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 25 MP a/ 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperatures:

- Steam: + 550 °C (+ 1022 °F)

- Oxidising conditions: + 450 °C (+ 842 °F)

- Non-oxidising conditions: + 850 °C (+ 1562 °F)

- Minimum operating temperature: – 200 °C (- 328 °F)

- Maximum system pressure: 2.5 MPa / 25 bar (363 psi)

- Maximum shaft speed: 25 m/s (4921 fpm)

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents. Negligible volatile content. Low in extractable trace impurities such as chloride and sulphur.

How supplied

- All popular square sections from 3 mm (1/8“) upwards, in boxes containing 8 m (26′ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

A premier quality graphite packing for valves with corrosion inhibitors.

Formerly known as Grafpak, Lionpak® 5300 is a dense, high strength packing of cross-plaited premier quality graphite filament yarns.

Treated with pure graphite before and after plaiting, and further treated with corrosion inhibitors.

A cost effective alternative is also available, please download the Lionpak® 5303 datasheet for full details and specification.

Product features

- Suitable for a wide range of aggressive media at elevated temperatures

- Low friction for low torque valve action

- Tough and resistant to fretting and extrusion

Typical applications

- Control valves and main stop valves on high temperature / pressure steam circuits at power stations, chemical plants, industrial services, and on marine installations

- Also suitable for duties with water, condensate, alkalis, acids, solvents and most chemicals

Performance

Valve Stem Duties

- Maximum operating temperatures:

- Steam: + 550 °C (+ 1022 °F)

- Oxidising conditions: + 550 °C (+ 1022 °F)

- Non-oxidising conditions: Significantly higher, please contact us for further details.

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure (typical): 15 MPa / 150 bar (2175 psi)

- Please contact us for details on higher pressure duties.

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 3 mm (1/8“) upwards, in boxes containing 8 m (26′ 3”), in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

A specialised packing with carbon fibre strength, low friction and heat dissipation.

Lionpak® 5301 is a tough, high performance packing inter-braided from carbon fibre yarn.

It is impregnated with James Walker®’s proprietary graphite-based dispersion as a blocking agent, and a molybdenum based corrosion inhibitor.

Product features

- Strong, pliable and abrasion resistant

- Excellent heat dissipation and low friction qualities

- Inter-braiding plus blocking agent ensures leak-free construction

- Corrosion inhibitor prevents galvanic corrosion when used on applications with steam

Typical applications

Valves, pumps, mixers, reactors and agitators, handling steam, acids, alkalis, solvents, organic chemicals, gases and thermic fluids such as molten salt.

Performance

Valve Stem Duties

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 20 MPa / 200 bar (2900 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 450 °C (+842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Lionpak® 5301 may be suitable for higher pressures on certain reciprocating duties, please contact us for details.

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 3 mm (1/8“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A specialised graphite / carbon fibre packing for chemical and abrasion resistance.

Lionpak® 5302 is a specially developed packing that combines the advantages of soft expanded high purity 99% graphite yarn with the toughness of carbon fibre yarn at its four corners.

It is impregnated with James Walker®’s proprietary, high temperature, graphite-based dispersion and an inorganic passive corrosion inhibitor.

Product features

- Recommended for applications at high working temperatures with corrosive media

- Good resistance to abrasion and wear

- Excellent dry-running capabilities that reduce the need for continuous water flushing

- Readily adapts to worn / pitted surfaces for smooth running under adverse mechanical conditions

- Corrosion inhibitor safeguards metallic interfaces from galvanic corrosion

Typical applications

- Pumps, valves, autoclaves, converters, mixers and reactors

- Suitable for duties with steam, acids and alkalis, hydrocarbons, fuel and lubricating oils, FCC catalyst and bottom slurry, hydrogen sulphide, sulphur dioxide, thermic fluid, and abrasive media such as ash slurry, fly ash water and sea water

Performance

Valve Stem Duties

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 450 °C (+ 842 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 6.5 mm (1/4“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A specialised carbon fibre packing for chemical resistance and low friction.

Lionpak® 5304 is a high grade packing of interlock-braided carbon fibre coated in PTFE.

The packing is thoroughly impregnated with James Walker®’s proprietary suspension to enhance sealability. This suspension is based on graphite, high temperature lubricant and corrosion inhibitors.

Product features

- Tough carbon fibre construction capable of handling steam, as well as the highly corrosive chemicals and abrasive media used in metallurgical processing plant

- Entrapping the suspension in a braided carbon fibre matrix increases lubrication as well as acting as a blocking agent

- Corrosion inhibitor safeguards metallic interfaces from galvanic corrosion

Typical applications

- Pumps, valves, reactors, agitators, mixers and other static or dynamic equipment in metallurgical processing and general industry

- Suitable for duties with steam and hot water, caustic chemicals (such as sodium hydroxide, potassium nitride, etc), acids and alkalis, organic chemicals, dry powder and thermic fluids

Performance

Valve Stem Duties

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 20 MPa / 200 bar (2900 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 260 °C (+ 500 °F)

- Minimum operating temperature: – 100 °C (- 148 °F)

- Maximum system pressure: 15 MPa / 150 bar (2175 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Lionpak® 5304 may be suitable for higher pressures on certain reciprocating duties, please contact us for details.

Chemical properties

Compatible with media in the range pH 0-14, excluding strong oxidising agents.

How supplied

- All popular square sections from 3 mm (1/8“) to 50 mm (2″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A synthetic packing with silicone free lubrication.

Formerly known as Fluolion Emulsion XA-P, Lionpak® 9100 is a universal packing comprising a unique synthetic yarn, densified with particles of PTFE and treated with an advanced silicone-free lubricant.

The impregnated yarns are cross-plaited over an elastomeric core, which enables this packing to absorb the eccentric actions of worn shafts and bearings running in very harsh environments.

Cost effective alternatives are also available, please download the Lionpak® 9101 and Lionpak® 9102 datasheets for full details and specification.

Product features

- Excellent chemical resistance

- Excellent abrasion resistance

- Low friction and low wear on shaft sleeves

- Contains non-contaminating lubricants

Typical applications

- Pumps, valves and rotating plant that handle hot, abrasive and highly caustic fluid media.

- This packing is widely used in contact with hot slurries and effluents at pulp and paper mills and alumina processing plants. It is also employed as a general purpose packing in the chemical industry

Performance

Valve Stem Duties

- Maximum operating temperature: + 270 °C (+ 518 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: +270 °C (+ 518 °F)

- Minimum operating temperature: – 50 °C (-58 °F)

- Maximum system pressure: 2.5 MPa/ 25 bar (363 psi)

- Maximum shaft speed: 20 m/s (3937 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 270 °C (+ 518 °F)

- Minimum operating temperature: – 50 °C (- 58 °F)

- Maximum system pressure: 10 MPa / 100 bar (1450 psi)

- Maximum rod speed: 1 m/s (197 fpm)

Chemical properties

Compatible with media in the range pH 1-14.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A versatile natural yarn packing with PTFE lubrication.

Formerly known as Ramiex, Lionpak® 9500 is a versatile, high-performance packing, cross-plaited from top quality bleached ramie fibre yarns that are impregnated with an advanced PTFE dispersion lubricant. The result is a consistent packing of uniform density and compressibility.

Ramie, a tropical nettle plant, produces a fibre of extreme durability, rot resistance and significantly greater strength than flax, cotton or hemp.

A cost effective alternative is also available, please download the Lionpak® 9501 datasheet for full details and specification.

Product features

- Outstanding extrusion resistance

- Outstanding abrasion resistance

- Outstanding rot resistance

- Low friction and low wear

- Kind to shafts and sleeves

Typical applications

- Used with great success in the mining and quarrying industries on reciprocating pumps working at 30 MPa with water containing highly abrasive particles

- Also used for water-based hydraulic systems, pulp and paper processing with cellulose slurry, brine circulation, cooling water systems, and with fluids that crystallise or contain suspended solids

Performance

Valve Stem Duties

- Maximum operating temperature: + 120 °C (+ 248 °F)

- Minimum operating temperature: – 30 °C (- 22 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

Centrifugal Pumps and Rotary Equipment

- Maximum operating temperature: + 120 °C (+ 248 °F)

- Minimum operating temperature: – 30 °C (- 22 °F)

- Maximum system pressure: 2 MPa / 20 bar (290 psi)

- Maximum shaft speed: 17.5 m/s (3445 fpm)

Reciprocating Pumps and Rams

- Maximum operating temperature: + 120 °C (+ 248 °F)

- Minimum operating temperature: – 30 °C (- 22 °F)

- Maximum system pressure: 25 MPa / 250 bar (3626 psi)

- Maximum rod speed: 2 m/s (394 fpm)

Chemical properties

Compatible with media in the range pH 4-11.

How supplied

- All popular square sections from 3 mm (1/8“) to 25 mm (1″) in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

A nonhazardous fibre packing for very high temperature applications.

Formerly known as Valcor Hi-Temp, Lionpak® 9600 is a compression packing for very high temperature duties.

It is manufactured from an exceptionally stable fibre material that is soft, non-irritating, non-hazardous, and is not limited by World Health Organisation or European Union restrictions.

The yarn is spun into a flexible yarn and with low percentage of glass fibre and Inconel wire reinforcement. It contains no organic agents or processing additives. It therefore retains its physical and chemical properties at very high temperatures and does not decompose into hazardous substances.

A cost effective alternative is also available, please download the Lionpak® 9603 datasheet for full details and specification.

Product features

- Non-hazardous heat resistant fibre construction

- Alternative for normal ceramic fibre packings

- Good chemical compatibility

Typical applications

- Recommended for very high temperature static sealing duties or slow rotary applications

- It replaces ceramic yarn packing and radiation seals on BOS plant, and ceramic packings and vessel lid seals on secondary steelmaking plant

- Other examples include door seals for annealing furnaces at steelworks, kiln packings, protective surfaces on pottery kiln cars, and stem gland sealing on valves handling very high temperature gases

- Other constructions include braided insulation sleeves, webbing tapes, ladder tapes, twisted ropes, lagging ropes, blankets and paper, and woven cloth

Performance

Static and Slow Rotary Duties Only

- Maximum operating temperature (constant): + 1000 °C (+ 1832 °F)

- Maximum operating temperature (intermittent): + 1100 °C (+ 2012 °F)

- Minimum working temperature: – 50 °C (- 58 °F)

Chemical properties

Compatible with media in the range pH 0 -10, excluding hydrofluoric acid and hydrogen fluoride. It has excellent resistance to water, organic chemicals and other acids.

How supplied

- Available as densely braided compression packings – square, round and rectangular – in sections from 5 mm (8/16“) to 100 mm (4″) and in any length in boxes containing 8 m (26′ 3”) in coil form or on spools as detailed in the product datasheet

- Also supplied as split preformed rings and sets

- Please refer to the product datasheet for spool ordering information

- Other constructions are manufactured to order

Health and safety considerations

- Average diameter of the mineral fibre used is 9 μm (354 μin), which is considered non-hazardous to health. No protection for breathing, eye, hand or body is required by the World Health Organisation or European Union during the product’s normal storage, handling and use.

- For further details please contact us to request a copy of our Safety Data Sheet (SDS). Please note that normal ceramic fibres, as often used in the manufacture of very high temperature compression packings, are around 3 μm (118 μin) in diameter. These much finer fibres are now considered hazardous to health, with WHO and EU

- restrictions applied to the products that contain them.

Approvals & certifications

- Classified as non-carcinogens according to the criteria of note Q in European Directive 97/69/EC