Safety is Power, The Worlds Strongest Self-locking Nut!

HARDLOCK® set screws have been adopted as the new adaptive solution for holding pins in place. Companies such as Toyota, Honda, Nissan and Tesla in the automotive industry have realized the potential for HARDLOCK® set screw, reviewing their current die casting machine designs. One example is Tesla’s use of the product in the Giga Press Machine (aluminium die casting machine). HARDLOCK® set screw has also been adopted as a standard solution for injection molding machines (plastic).

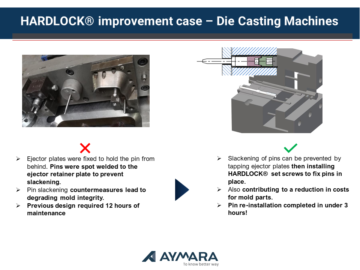

Up until now the standard solution was to use ejector plates fixed with bolts to reduce pin wear and obtain proper positioning of the pins. For large molds ejector plate’s are heavy and take time to install. Other methods such as spot welding were used to hold the pins in place, but reduces the integrity of the mold itself, and makes exchanging of the pin extremely difficult.

HARDLOCK® set screw acts as a grub screw with an extended tie rod allowing for fixing of pins. The HARDLOCK® set screw consists of 2 grub screws, where the first screw has an extended tie rod fixing the pin in place. The second grub screw has a tapered section which is off-centred that joints into the first screw. The wedging effect which takes place reduces play and applying friction to the threads preventing the screw from loosening. This new solution allows for simple installation and removal of the pins without ruining the integrity of the mold. HARDLOCK® set screw is also reusable.

Learn more: HARDLOCK®

To send a detail and summary UP-TO-DATE presentation please contact us on info@aymara.cz (Czech, English and Polish version).